Главная /Warehouse solutions /Conveyor systems /

Roller conveyors

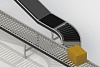

Roller conveyors are a mechanism consisting of a set of spaced apart rollers with axles mounted on both sides on a common frame. The variety of roller conveyor configurations has earned them widespread popularity in various industries and warehousing logistics.

Описание

According to the most common classification, roller conveyors are divided into driven and non-driven, straight and slewing, diverting and feeding.

Roller conveyors are best suited for transporting packaged/palletised goods with a flat, firm and straight bottom, without convex areas or irregularities that can cause the goods to jam in the mechanism and tip over.

Non-driven roller conveyors (roller conveyors) operate by gravity (force of gravity), so tend to be at a slight angle, and are suitable for moving items over short distances of up to 5 metres. The mechanism most commonly used is cylindrical rollers placed at an angle of 10−20° to the main axis. The absence of a driving mechanism means that the price of the equipment is quite low, so the use of non-driven roller conveyors is justified in order to reduce the overall cost of the project when installing long conveyor lines.

Driven roller conveyors are used in production and storage plants where the uniformity of movement pace and conveyor performance is required. Due to the use of a drive mechanism in the conveyor, the transport line can be given any direction, including lifting loads. The configuration of the drive conveyors (direction, roller diameter, distance between rollers, incline angle) depends on the characteristics (shape, weight and packaging) of the goods to be transported and the individual characteristics and tasks of the production/warehousing facility.